Client: A leading food corporation in South Korea

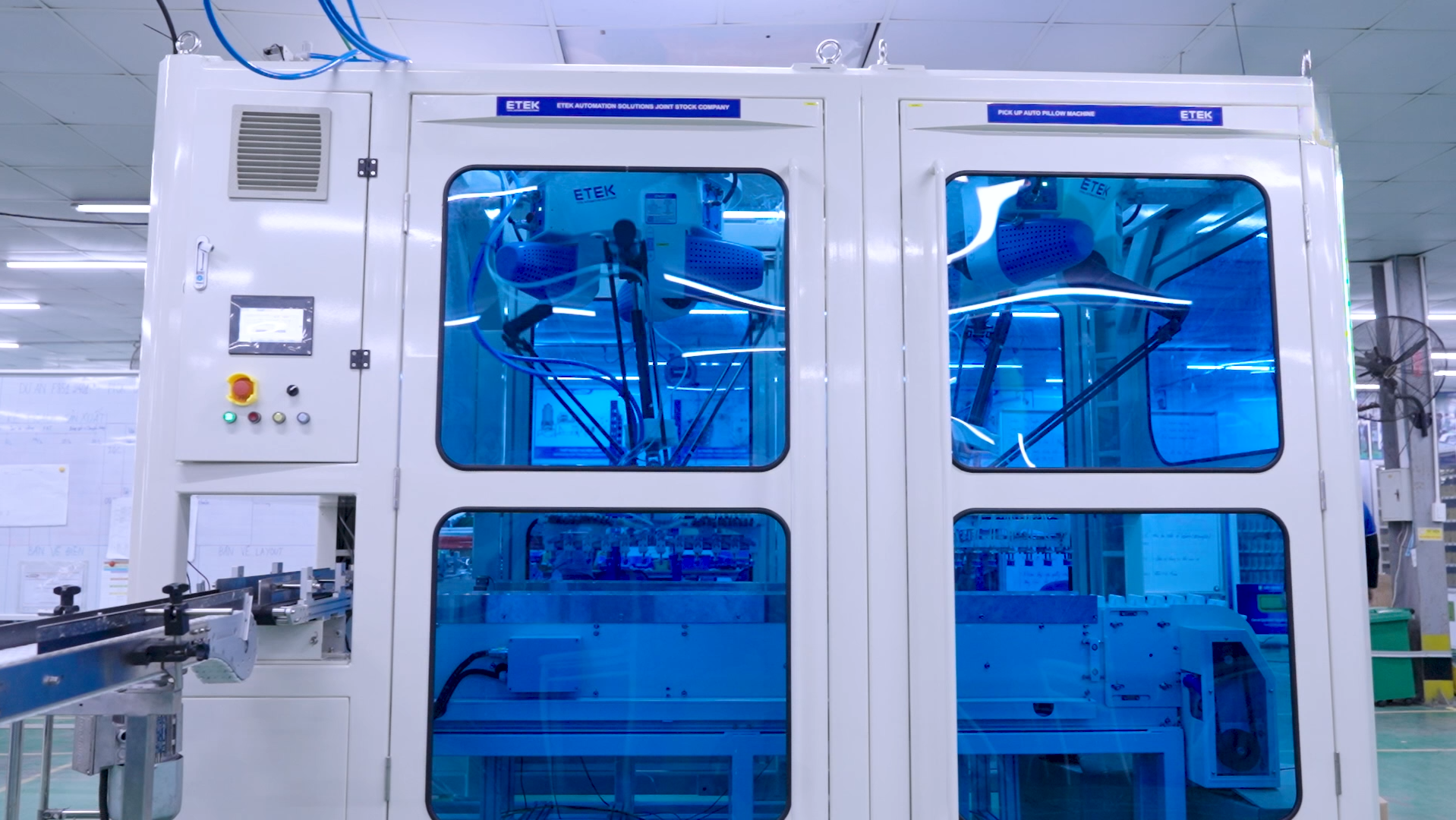

Number of stations: 03 high-speed product picking stations

Export market: South Korea

This is a flagship project that was 100% designed and manufactured in Vietnam, then directly exported to South Korea – one of the most demanding markets in terms of technical requirements and industry standards. The success of this project not only affirms Vietnam’s capability in localizing automation equipment but also marks an important milestone in bringing “Made in Vietnam” technology to the global stage.

Challenges

The client operates a modern production system in compliance with international standards of safety, quality, and efficiency. Given the specific requirements of the food industry, the automation system had to meet strict conditions:

- Continuous and stable operation with minimal downtime.

- Design and materials ensuring food safety, easy cleaning, and prevention of cross-contamination.

- Processing speed of 432 products per minute without damaging or deforming the products.

- Standardized installation, wiring, and design in compliance with South Korean factory regulations.

- Optimized layout to save space and enable seamless integration into the existing production line.

Optimized layout to save space and enable seamless integration into the existing production line.

Our Solution

Leveraging extensive experience in high-speed pick & place systems, the Tân Phát ETEK engineering team developed a comprehensive solution with the following highlights:

- Precision mechanics combined with intelligent control to ensure performance and stability.

- Transparent project execution process with strict quality control from design to manufacturing.

- Easy maintenance and scalability to meet future expansion needs.

System Specifications

- Dimensions: 3250 x 2200 x 2540 mm

- Product handled: Packaged biscuits

- Capacity: 432 products/minute

- Power supply: 1 Phase – 220 VAC, 7 kW

Main Components

- Machine frame: Supports the entire system and integrates the control cabinet.

- Machine frame: Supports the entire system and integrates the control cabinet.

- Tray-loading conveyor: PVC conveyor driven by a servo motor, designed to accelerate and create spacing between products.

- Delta Robot & Tool: Picks and places products using flexible vacuum grippers with adjustable spacing to match product dimensions.

Results Achieved

- Project completed on schedule despite tight delivery timelines.

- Fully met the stringent technical standards of South Korea.

- Reinforced the credibility and engineering capabilities of Vietnamese experts.

- Opened up new opportunities for export to international markets.

Expansion Potential

The system was developed with high flexibility, allowing easy adjustments to handle various products of different shapes, sizes, and materials. It can be widely applied in:

- Food & Beverage

- Cosmetics & Pharmaceuticals

- FMCG (Fast-Moving Consumer Goods)

From confectionery, bottles, and detergent pouches to specialized packaged goods, this solution helps customers optimize investment costs, enhance operational efficiency, and expand production capacity.

Tân Phát ETEK’s high-speed product picking system is a testament to Vietnam’s innovation and manufacturing excellence, marking a strong “Made in Vietnam” footprint on the global automation technology map.

Delta Robot Case Packer_Giải pháp robot sắp xếp sản phẩm vào khay tự động